Rostec has commissioned the first assembly and testing complex for ship units in the Russian Federation

February 13, 2025

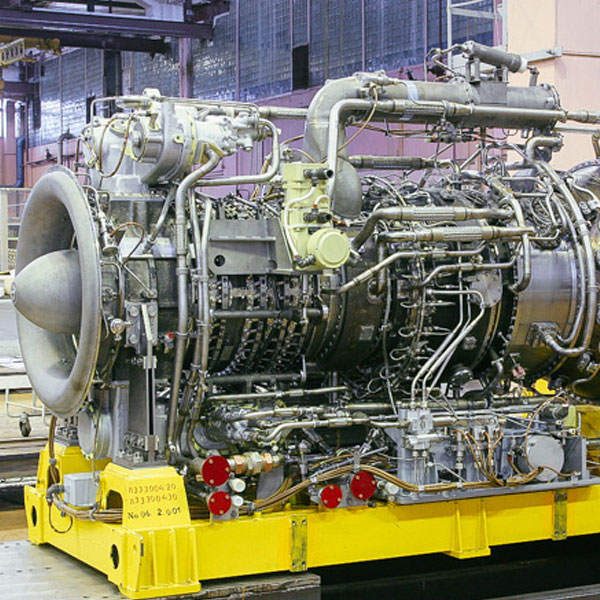

Rostec has commissioned the first Russian assembly and test complex for gas turbine units (GTU) for marine programs at the Rybinsk enterprise NPO Saturn, which is part of the United Engine Corporation.

The development of the Russian base for marine gas turbine construction is being implemented within the framework of the import substitution program. One of the most important objectives of the project is to create a test base for all types of testing of marine units simulating real operating conditions. In addition, the assembly and test complex will be used for the implementation of experimental design work, technological re-equipment and preparation for the production of marine GTUs. The estimated cost of construction is more than 6.7 billion rubles.

The assembly and test complex is based on two stands: the first with a capacity of up to 15 MW, the second up to 40 MW. It is possible to test both the entire power plant and its components. For example, a diesel-gas turbine unit includes a diesel engine, a gas turbine engine, a marine gearbox, and local control systems. One of the features of the unique complex is the maximum automation of work processes, in particular, the system for collecting measurement data.

At the moment, the new facility has started pre-delivery tests of the M35R-1 unit, which is used as part of the world's largest hovercraft as a drive for the propeller. The unit includes the M70FRU-2 engine, gearbox, transmissions connecting them, and a control system). The feature of the M70FRU-2 is increased efficiency and service life between repairs compared to previously used analogs. Both the unit and the engine are developed by NPO Saturn.

"Today, Rostec enterprises have all the competencies in developing marine engines and have prototypes in this area in their line of promising products. The opening of the complex will allow us to establish production and maintenance of power plants for the Russian Navy by 2018. Technological solutions incorporated into the design of the facility allow testing ship units of more than 20 different configurations," said Sergey Chemezov, CEO of Rostec State Corporation.

“The implementation of the import substitution program, which to a greater or lesser extent affected all product lines of UEC, is a serious task for our holding, said Alexander Artyukhov, CEO of the United Engine Corporation. — Carrying out a range of works on marine topics, we have mastered a new important competence in terms of conducting a full range of tests of marine engines and units based on them, which will meet the needs of the Russian Navy in marine power plants."

Within the framework of the creation of the Russian marine gas turbine construction base, experimental design work is being carried out, which will allow, from 2018, to switch to serial production of M70FRU, M70FRU-2, M70FRU-R, M90FR engines, M35R and M70 units, as well as units based on promising products with modernized gearbox complexes and control systems.

Together with NPO Saturn, the gas turbine engineering research and production centers Salyut and UEC-STAR, which are part of UEC, as well as a number of other enterprises and industry institutes, are participating in the implementation of marine programs. CIAM, Plant "Fiolent", UNPP "Molniya" and others.

Shipbuilding

News

from the company TransTechnology