"TRANSTECHNOLOGY" produces

Pneumatic roller-bag for launching vessels into the water

The pneumatic roller bag for ship launching is an innovative technology with brilliant prospects in shipbuilding. This flexible launching technology now offers full advantages such as labor savings, time savings, workload reduction, investment efficiency, flexibility, safety, and reliability.

The air cushion launching technology overcomes the limitations of traditional sliding methods typically used in small and medium vessel construction, even for ships up to 60,000 DWT.

How does the roller bag work?

All you need is a slipway free of sharp objects, a slipway winch with accessories like steel cables and shackles to provide necessary pulling force, and the air bags themselves.

The deflated rollers are then inserted under the ship's hull and inflated to lift the vessel.

Designed with high load-bearing capacity, the rollers launch ships into water (or retrieve them, depending on application) through their rolling capability.

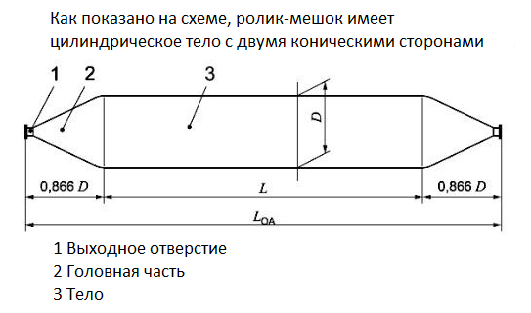

The pneumatic launching roller bag, whose main body consists of rubber layers reinforced with synthetic cord, features cylindrical air bags with hemispherical heads at both ends. The fully vulcanized system contains compressed internal air that enables rolling motion.

Materials

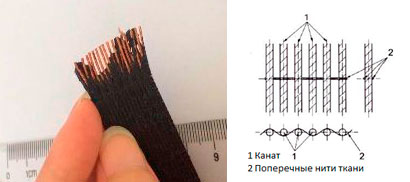

Roller bags are constructed with an outer rubber layer, one or multiple synthetic cord reinforcement layers, and an inner rubber layer. The synthetic cord reinforcement layout is shown in the diagram below, with all materials securely vulcanized.

Before manufacturing, outer and inner rubber layers must meet testing criteria specified in the following table, according to methods listed in international standards.

While tests 1-3 require only one satisfactory sample per batch, tests 4-9 must be conducted annually. If the first sample fails, two additional samples must be tested. Passing these additional samples qualifies the materials; otherwise, the batch is rejected and alternative materials selected.

Rubber Material Requirements

| No. | Test | Criteria | Method | |

| 1 | Tensile strength, MPa | ≥18 | ISO 37 | |

| 2 | Elongation at break % | ≥400 | ISO 37 | |

| 3 | Shore hardness | 60±10 | ISO 7629-1 | |

| 4 | Tear strength N/cm | ≥400 | ISO 34-1 | |

| 5 | Compression set %(70℃±1℃ 22h) | ≤30 | ISO 815-1 | |

| 6 | After heat aging 70℃±1℃ 96h |

Tensile strength retention % | ≥80 | ISO 188 |

| 7 | Elongation retention % | ≥80 | ISO 188 | |

| 8 | Shore hardness change | ≤8 | ISO 7619-1 | |

| 9 | Ozone aging 40℃x96h Ozone concentration (50℃±5x108), 20% strain |

No cracks | ISO 1431-1 | |

Roller Bag Applications

- Ship modernization, conversion, or new/repair vessel launching (launching roller bags)

- Salvaging sunken ships or heavy submerged steel structures

- Lifting and transporting heavy loads up to 10,000 tons on land

- As fender devices for collision protection between vessels

- As containers for storing/transporting gas, aggressive chemical liquids, and clean water for voyages

- For ship ballasting

Vessel Launching Requirements: Ship and Necessary Equipment

1 Vessel

All underwater engineering work must be completed, particularly equipment, valves, etc. installed below the waterline, with inspection approval. All burrs, welds, etc. on hull bottoms or appendages must be ground smooth. All shell plate welds must pass leak testing. Main vessel dimensions must be measured, and load line marks verified. All hull painting must be finished.

2 Slipway

The roller path must be clean, free of sharp protrusions like stones or debris. The track must be leveled with left-right level error under 80mm. Depressions must be filled with relatively even load-bearing capacity. The slipway should have polished soil, sand, or concrete with bearing capacity twice the airbag working pressure. Slope angle depends on vessel size, typically not exceeding 1/7 (optimal 5-6°). The entire path may combine multiple slope lines, but the hull must never ground, even at minimum airbag height. The slipway must extend underwater sufficiently.

3. Winch

Typically a slow winch (9-13 m/min rotation speed) is selected. Vessel speed shouldn't exceed 6 m/min with winch pull control. For sub-200t vessels, speed may increase appropriately. Cables must be inspected and regularly replaced.

4. Compressor

Select compressor type/capacity based on total airbag volume, required inflation time, and air pressure. Install with adjustable pressure relief valve.

Safety Measures

Overpressure control:

Strictly control working pressure - overpressure is prohibited.

Slipway requirements:

Use earthen or concrete slipways according to vessel tonnage.

Avoid sharp objects:

Ensure no sharp objects contact rollers during use, with clean, even surfaces during failures.

Avoid distortion and overload::

Prevent longitudinal distortion during rolling and avoid overloading after inflation.

Roller Bag Parameters

| Size | GUARANTEED WORKING PRESSURE | |||||

|

Type |

D=0.8m |

D=1.0m |

D=1.2m |

D=1.5m |

D=1.8m |

D=2.0m |

|

FL 3-layer |

0.13MPA |

0.10MPA |

0.09MPA |

0.07MPA |

0.06MPA |

0.05MPA |

|

FL 4-layer |

0.17MPA |

0.13MPA |

0.11MPA |

0.09MPA |

0.08MPA |

0.07MPA |

|

FL 5-layer |

0.21MPA |

0.17MPA |

0.14MPA |

0.11MPA |

0.09MPA |

0.08MPA |

|

FL 6-layer |

0.25MPA |

0.20MPA |

0.17MPA |

0.13MPA |

0.11MPA |

0.10MPA |

|

FL 7-layer |

0.29MPA |

0.23MPA |

0.20MPA |

0.15MPA |

0.13MPA |

0.12MPA |

|

FL 8-layer |

0.33MPA |

0.26MPA |

0.23MPA |

0.17MPA |

0.15MPA |

0.14MPA |

|

FL 9-layer |

0.37MPA |

0.29MPA |

0.26MPA |

0.19MPA |

0.17MPA |

0.16MPA |

|

FL 10-layer |

0.41MPA |

0.32MPA |

0.29MPA |

0.21MPA |

0.19MPA |

0.18MPA |

|

FL 11-layer |

0.45MPA |

0.35MPA |

0.31MPA |

0.23MPA |

0.21MPA |

0.20MPA |

|

FL 12-layer |

0.49MPA |

0.38MPA |

0.34MPA |

0.25MPA |

0.23MPA |

0.22MPA |

Launching Load Capacity (6 layers)

|

Diameter |

Working pressure | Working height | Guaranteed load capacity per unit length | ||

| kN/m | t/m | 1b/ft | |||

| 0.5m(1.640ft) | 117.92 | 12.02 | 8079 | ||

| D=0.8m | 0.25MPA | 0.4m(1.312ft) | 157.16 | 16.02 | 10768 |

| (D=2.62ft) | (18.85psi) | 0.3m(0.984ft) | 196.49 | 20.03 | 13463 |

| 0.2m(0.656ft) | 235.73 | 24.03 | 16151 | ||

| 0.6m(1.968ft) | 125.76 | 12.82 | 8617 | ||

| 0.5m(1.640ft) | 157.16 | 16.02 | 10768 | ||

| D=1.0m | 0.20MPA | 0.4m(1.312ft) | 188.65 | 19.23 | 12925 |

| (D=3.28ft) | (14.50psi) | 0.3m(0.984ft) | 220.04 | 22.43" | 15076 |

| 0.2m(0.656ft) | 251.53 | 25.64 | 17233 | ||

| 0.7m(2.296ft | 133.61 | 13.62 | 9154 | ||

| 0.6m(1.968ft) | 160.3 | 16.34 | 10983 | ||

| D=1.2m | 0.17MPA | 0.5m(1.640ft) | 187.08 | 19.07 | 12818 |

| (D=3.94ft) | (13.05psi) | 0.4m(1.312ft) | 213.76 | 21.79 | 14646 |

| 0.3m(0.984ft) | 240.44 | 24.51 | 16474 | ||

| 0.2m(0.656ft) | 267.22 | 27.24 | 18309 | ||

| 0.9m(2.952ft) | 122.63 | 12.5 | 8402 | ||

| 0.8m(2.624ft) | 143.03 | 14.58 | 9800 | ||

| 0.7m(2.296ft | 163.43 | 16.66 | 11198 | ||

| D=1.5m | 0.13MPA | 0.6m(1.968ft) | 183.94 | 18.75 | 12602 |

| (D=4.92ft) | (10.15psi) | 0.5m(1.640ft) | 204.34 | 20.83 | 14000 |

| 0.4m(1.312ft) | 224.75 | 22.91 | 15398 | ||

| 0.3m(0.984ft) | 245.15 | 24.99 | 16797 | ||

| 0.2m(0.656ft) | 267.81 | 27.3 | 18349 | ||

| 1.1m(3.608ft) | 120.96 | 12.33 | 8287 | ||

| 1.0m(3.280ft) | 138.22 | 14.09 | 9470 | ||

| 0.9m(2.952ft) | 155.59 | 15.86 | 10660 | ||

| 0.8m(2.624ft) | 172.85 | 17.62 | 11843 | ||

| D=1.8m | 0.11MPA | 0.7m(2.296ft | 190.22 | 19.39 | 13033 |

| D=5.90ft | (8.70psi) | 0.6m(1.968ft) | 207.48 | 21.15 | 14216 |

| 0.5m(1.640ft) | 224.75 | 22.91 | 15398 | ||

| 0.4m(1.312ft) | 242.01 | 24.67 | 16581 | ||

| 0.3m(0.984ft) | 259.38 | 26.44 | 17771 | ||

| 0.2m(0.656ft) | 276.64 | 28.2 | 18954 | ||

| 1.2m(3.936ft) | 125.76 | 12.82 | 8617 | ||

| 1.1m(3.608ft) | 141.46 | 14.42 | 9692 | ||

| 1.0m(3.280ft) | 157.16 | 16.02 | 10768 | ||

| 0.9m(2.952ft) | 172.85 | 17.62 | 11843 | ||

| D=2.0m | 0.10MPA | 0.8m(2.624ft) | 188.64 | 19.23 | 12925 |

| (D=6.56ft) | (7.25psi) | 0.7m(2.296ft | 204.34 | 20.83 | 14000 |

| 0.6m(1.968ft) | 220.04 | 22.43 | 15076 | ||

| 0.5m(1.640ft) | 235.73 | 24.03 | 16151 | ||

| 0.4m(1.312ft) | 251.43 | 25.63 | 17227 | ||

| 0.3m(0.984ft) | 267.13 | 27.23 | 18302 | ||

| 0.2m(0.656ft) | 282.92 | 28.84 | 19384 | ||

Vessel Buoyancy

Classification |

Standard roller bag | with 3,4 or 5 fabric cord layers | |||||

| High roller bag | with 6,7 or 8 fabric cord layers | ||||||

| Highest roller bag | with 9,10 or more upon request | ||||||

| Diameter | From 0.6 to 2.8m or customized | ||||||

| Permitted length | From 5m to 25m or other | ||||||

| Total length | From 7m to 28m or customized | ||||||

| Lifting capacity | From 3T to 60T buoyancy | ||||||

|

Effective length(m) |

Roller bag buoyancy (tons) | ||||||

| D=1m | D=1.2m | D=1.5m | D=1.8m | D=2m | |||

| 5 | 3.93 | 5.65 | 8.84 | 12.72 | 15.71 | ||

| 6 | 4.71 | 6.79 | 10.6 | 15.27 | 18.85 | ||

| 7 | 5.5 | 7.92 | 12.37 | 17.81 | 21.99 | ||

| 8 | 6.28 | 9.05 | 14.14 | 20.36 | 25.13 | ||

| 9 | 7.07 | 10.18 | 15.9 | 22.9 | 28.27 | ||

| 10 | 7.85 | 11.31 | 17.67 | 25.45 | 31.42 | ||

| 11 | 8.64 | 12.44 | 19.44 | 27.99 | 34.56 | ||

| 12 | 9.42 | 13.57 | 21.21 | 30.54 | 37.7 | ||

| 13 | 10.21 | 14.7 | 22.97 | 33.08 | 40.84 | ||

| 14 | 11 | 15.83 | 24.74 | 35.63 | 43.98 | ||

| 15 | 11.78 | 16.96 | 26.51 | 38.17 | 47.12 | ||

| 16 | 12.57 | 18.1 | 28.27 | 40.72 | 50.27 | ||

| 17 | 13.35 | 19.23 | 30.04 | 43.26 | 53.41 | ||

| 18 | 14.14 | 20.36 | 31.81 | 45.8 | 56.55 | ||

| 19 | 14.96 | 21.54 | 33.66 | 48.47 | 59.85 | ||

| 20 | 15.75 | 22.68 | 35.43 | 51.03 | 63.00 | ||

Storage

- Roller bags must be stored in dry, ventilated areas protected from light

- Store deflated, free from tension, compression or other deformations

- Keep away from heat sources

- Protect from acids, alkalis, oils or organic solvents

Shipbuilding

News

from the company TransTechnology